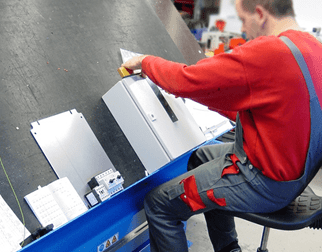

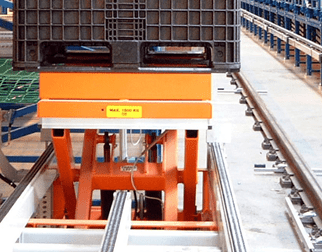

Ensure continuous operation

Keep your lift running. Keep your business moving. Every stop in your production flow affects more than just the schedule. That’s why TRANSLYFT goes beyond installation. From day one to end-of-life planning, we deliver service that protects uptime, extends equipment lifespan, and supports long-term performance.