- Overview

- Specifications

- Downloads

- Related

TP 3000

- Fast delivery

- Made in Denmark

- Plug & play

- Worldwide shipping

A lifting table with a single scissor is useful in many situations. It is extremely popular for bringing goods up to the most ideal height for the employee. This not only ensures better effici

Create your own customized solution tailored to your needs with our easy-to-use configurator

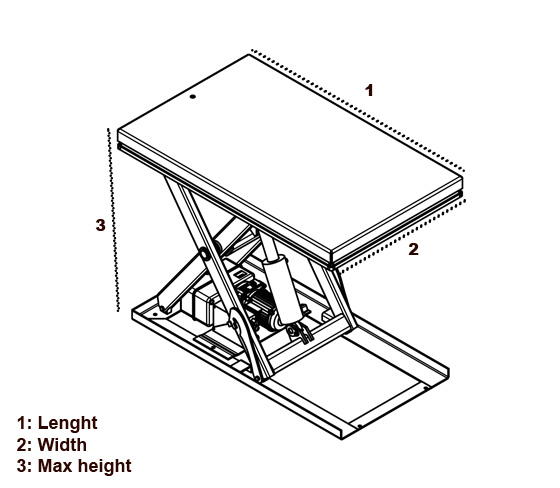

Technical specifications

| Capacity (kg): | 3000 |

| Travel (mm): | 2000 |

| Length (mm): | 3100 |

| Width (mm): | 1500 |

| Closed height (mm): | 400 |

| Max height (mm): | 2400 |

| Lift (sek.): | 55 |

| Engine (kw): | 3 |

| Net weight (kg): | 940 |

| Painted |

Downloads

- Certified Hygienic

- Better durability

- Improved ergonomics

- CE approved Stainless Steel and produced by the EHEDG guidelines

Our TRANSLYFT Hygienic Design lifting tables are manufactures in stainless steel AISI 304, 316 or higher.

- Better durability saves you money

Minimize the time spent on maintenance. Our components have a longer lifetime and are designed to minimize time spent on maintenance and cleaning

Got questions? Read our FAQ right here or contact us using mail or phone, and we will do our best to help you.

-

What is a lift table?

A lifting table, also known as a scissor lift table, is a work platform that can be raised and lowered to the desired height. It works using a scissor mechanism, allowing for ergonomic handling of heavy items and reducing the need for manual lifting.

They are frequently used to lift items in warehouses, factories, and other industrial environments. Hydraulics, electricity, or a combination of the two can power lifting tables. They are built to be safe and simple to operate, with features like safety trip bars, and emergency stop buttons to help prevent accidents and injuries.

-

How does a lift table work?Via a hydraulic system or a spindle and gear motor.

A lifting table consists of a base frame, the scissor, and a platform. Most systems use a hydraulic pump and an electric motor or manual labour motor to elevate the platform. An electric lifting table or a linear actuated lifting table uses a spindle and a gear motor to make the lift raise and lower the platform.

Simply set a pallet or other objects onto the lift platform, use the control box to elevate the lifting table to the best ergonomic work height. The best work height depends on the height of the person using the scissor lift. Working at the correct height positively influences the posture, health, and productivity of a worker, which makes a lifting table a good investment.

-

Types of lifting tables?

Lifting tables are classified into three types: hydraulic, manual, and electric powered lifts (an electric lifting table is also called a spindle or a linear actuated lifting table).

Moreover, lifting tables come in various configurations such as:

- Single scissor lifting tables

- Double and triple scissor lifting tables

- Horizontal double scissor lifting tables

- Low profile lifting tables

- Stainless steel hygienic lifting tables

- ATEX-certified lifting tables

And fully customized lifting solutions, that are specifically tailored to a specific working condition or environment.

At TRANSLYFT we have developed a 3D product builder, where you can easily customise the perfect lifting table for your needs. Check it out here.

-

What are the advantages of lifting tables?

A lifting table has several advantages, including being a safe and effective way to handle large items, reducing the risk of accidents and increasing production efficiency.

By minimizing heavy lifting processes, you will see an increase in employee efficiency since they will be less exhausted and more content, resulting in fewer sick days. Moreover, the capacity and production efficiency will increase for the employees.

There are other advantages depending on your specific industry. Using hygienic lifting tables can cut down on water use, cleaning time and allow for new orders, that your prior setup were not capable of handling. Moreover, by getting a lifting table with a higher capacity, you will be able to handler larger products, once again opening up new business opportunities.

The opportunities are many. Contact us to hear more, if you are looking to invest in new lifting equipment.

-

What are lifting tables used for?

A lifting table raises or lowers material to a desired height for easy access and handling.

Our lifting tables are used across many industries – from manufacturing, logistics, construction, transportation and packaging to the food and pharmaceutical sectors – wherever there’s a need to improve ergonomics, efficiency and capability.

-

What lifting capacities are available?

Our standard lifting tables handle capacities up to 3,000 kg. For custom solutions, we can accommodate other requirements as well, so please do not hesitate to contact us regarding other specification needs.

-

Can we deliver a customized lifting tables?

Absolutely. We specialise in customised lifting solutions designed around your specific working environment, processes, and ergonomic needs. In fact, 9 out of 10 lifts are customised to some extent. Contact us to hear more or try our 3d product builder.

-

Can lifting tables be used outdoors?

Yes. We offer galvanized models for outdoor use.

-

Can lifting tables be used in cleanroom environments?

Yes. We offer stainless steel lifting tables suitable for cleanroom or hygienic environments, including food and pharma.

-

Can lifting tables be used in ATEX environments?

Yes, We offer lifting tables suitable for ATEX (explosive safe) environments. Our lifts are certified and completely safe to use.

-

Are our lifting tables CE compliant?

Yes. All our lifting tables are CE marked and manufactured according to the European standard EN 1570, ensuring safety and compliance.

-

Do we offer service and maintenance contracts?

Yes. We offer flexible service agreements to ensure your lifting solution remains in optimal condition and meets all safety standards.

-

Where can you get spare parts or technical support?

We keep spare parts in stock and ship quickly. For assistance, contact us at spareparts@translyft.com or call +45 9886 4900.