Design your perfect lifting solution

Create your own customized solution tailored to your needs with our easy-to-use configurator

Our new Silverline series sets a new standard for non-bespoke lifting solutions.

Silverline lifting soluti

Create your own customized solution tailored to your needs with our easy-to-use configurator

| Capacity (kg): | 2000 |

| Travel (mm): | 1050 |

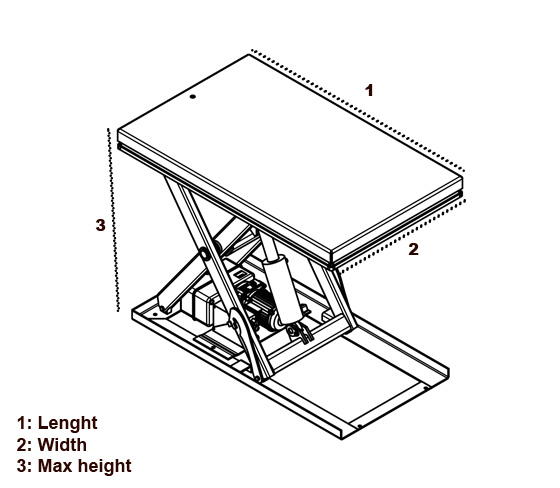

| Length (mm): | 1700 |

| Width (mm): | 1000 |

| Closed height (mm): | 250 |

| Max height (mm): | 1300 |

| Lift (sek.): | 25 |

| Engine (kw): | 1,5 |

| Net weight (kg): | 300 |

| Painted |